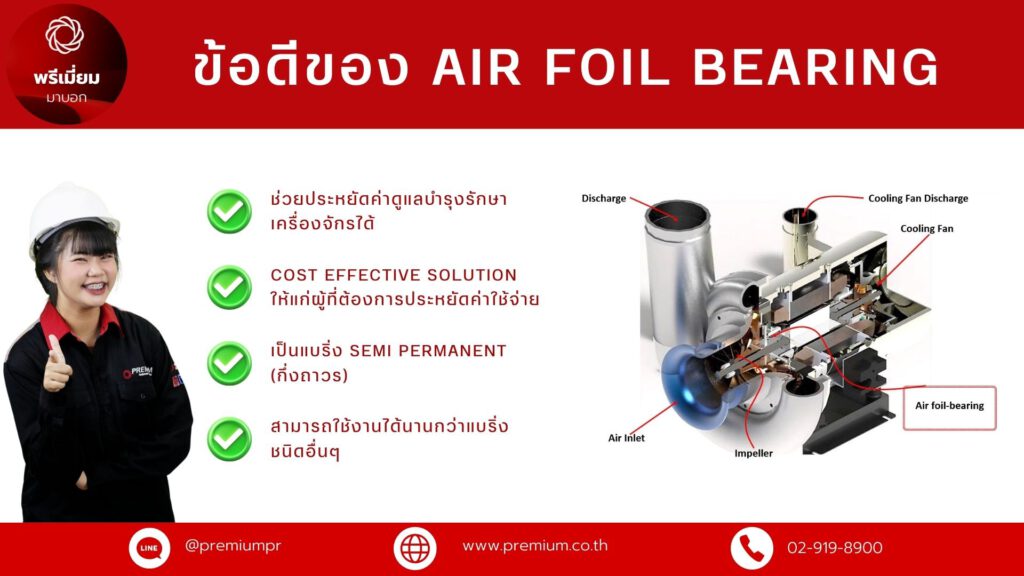

Air Foil Bearing แตกต่างจาก Bearing ชนิดอื่นอย่างไร

Since the air foil bearing doesn't require external ancillary equipment like electronic control systems, the bearing system has significantly fewer components. This construction makes it less prone to problems than other bearing systems used in high-speed turbo blowers. The rotor's backup bearings don't necessarily have air bearings.

Blowers APGNeuros HighSpeed Turbo… Treatment Plant Operator

Turbowin's WL Series is the most efficient air foil bearing turbo blower in the world paired with the highest efficiency up to 57.5% by the only air-cooling system without any additional water-cooling devices from 3HP to 2,100HP even though supplying vacuum air flow up to 420 Torr. WL Series has 10 kinds of product line-ups including Smart.

KSP Enterprises Ash Air Foil Bearing Turbo Blower at Rs 9500/piece in

Products/Services for Air Foil Bearing Turbo Blowers. Fans and Blowers (industrial) - (1485 companies) Industrial fans and blowers move air and powders in industrial and commercial settings. They commonly provide air circulation for personnel, exhaust, or material handling. Fans and blowers can provide spot cooling in industrial and commercial.

Air Foil Bearing Turbo Blower at best price in Bahadurgarh by Everest

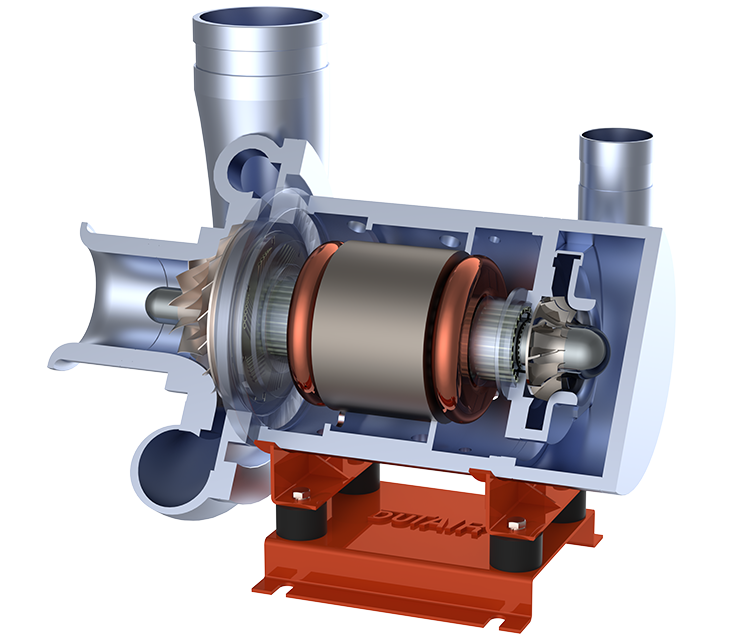

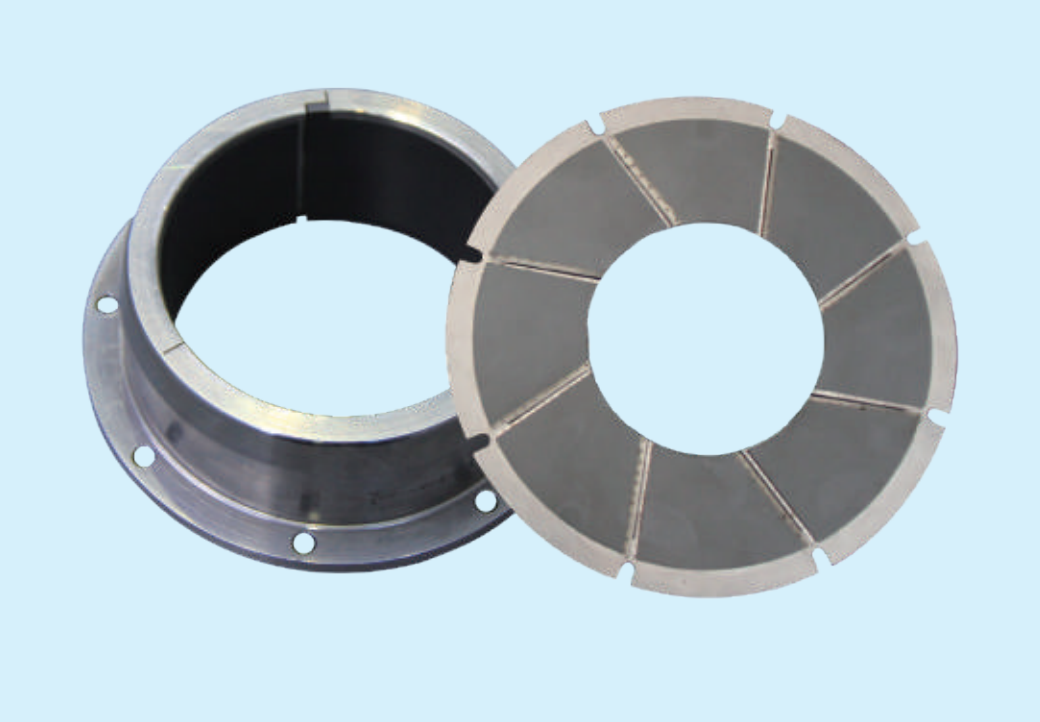

Air foil bearings generate a completely contactless transmission while the turbo blowers are operating, eliminating the mechanical losses as well as the use of oil or grease. Both axial and radial air foil bearings are applied to the permanent magnet rotor to keep the compressor and cooling impeller in position at all times.

Air Foil Bearing Turbo BlowerShandong Zhangqiu Blower Co.,Ltd

The Hoffman Revolution High-Speed Blower. By 2009, Korean-manufactured, high-speed turbo blowers using air-foil bearings, had begun to win some market share. Now a division of Quincy, Illinois based Gardner Denver Inc., Hoffman managers knew they had to respond. "High-speed blower imports, using air-foil bearings, could in certain.

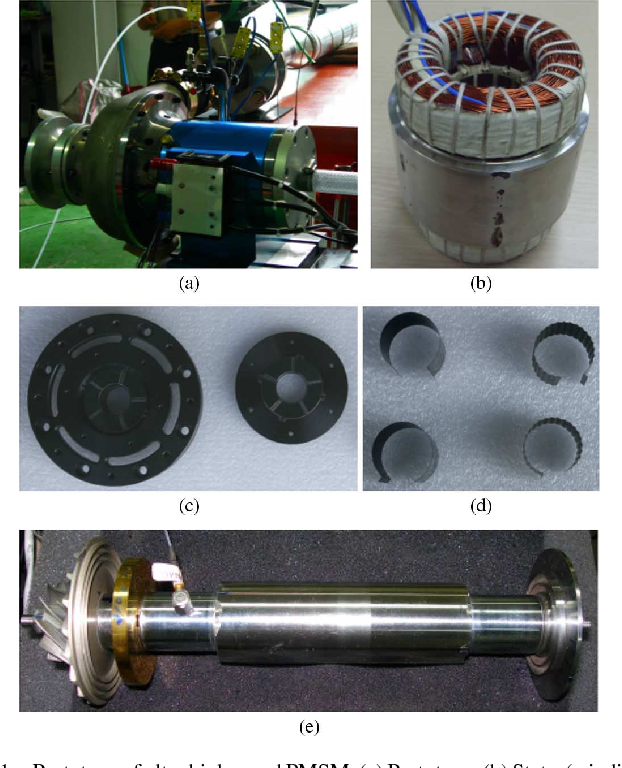

Figure 1 from Ultra High Speed Motor Supported by Air Foil Bearings for

Air Foil Bearings Requires no oil or grease—ever! Air foil technology has evolved substantially since the 1960s to become industry standard for military and commercial aviation. Simple and reliable these bearings are mechanical and do not require complicated control systems or external power to operate.

Air Foil Bearing Turbo Blower at best price in Bahadurgarh by Everest

Airfoil bearings vs. magnetic bearings in turbo blowers. April 22, 2020. Sponsored Content. Airfoil bearing: The shaft centers in the bearing itself and increases the pressure in the air gap to more than 30 bar. The prevailing force couples are so high, that they keep the shaft permanently in the center of the bearing even in case of.

Turbo Blower Air Foil Bearing Blower Capacity Up To 16500 M3/hr at

This is why AERZEN uses only air for the complex bearing within the turbo blowers. Neither oil nor other lubricants are necessary - but simply air. Air foil bearings in cross section: • Shaft centers itself automatically with increasing speed, an internal pressure of up to 30 bar is built up

Raetts Air Bearing Blower Air Foil Bearing Turbo Blower By Raetts

Turbo Blowers: Air Foil Bearing vs. Magnet Bearing June 6, 2019 Aerzen Turbo Blower air foil bearings feature simple construction with reliable technology, without additional battery or power sources.

The ideal compressor by Dutair Turbo blower technology, Air foil

Air Foil Bearings (AFB) has merged into the market for applications of high speed machinery, such as Air Cycle Machine, turbo blowers and micro gas turbine. Main driver being oil free applications. There remains strong interests in AFB developments and patents filing, initially from US, Korean and now Japan and Chinese.

The ideal compressor by Dutair Turbo blower technology, Air foil

The Aerzen Turbo Blowers' shafts are supported by air foil bearings and the high frequency drive concept does not make use of any speed increasing gears. There is no need for oil lubrication, therefore no worrying about maintenance, oil leakage or disposal problems. High Frequency Permanent Magnet Motor The motor is specifically designed

Air Foil Bearing Turbo BlowerShandong Zhangqiu Blower Co.,Ltd

AERZEN air foil bearing: more than one step ahead!Construction and functional principle of a turbo blower from AERZEN are simple and at the same time effecti.

Air Foil Bearing Turbo Blower Manufacturer Supplier from Mumbai India

Air foil bearings use the latter approach and as such they are a type of dynamic gas bearing. Air foil bearings were developed by NASA in the 1960s and 1970s, specifically for turbomachinery applications. In the air foil design, the space between rotating shaft and stationary housing contains two thin foils, made of metal coated with a low.

vs. air foil bearing Finding the best bearing solution for

In the paper, the development of high-speed industrial turbo blowers with foil air bearings is presented as a first successful commercialization in the world. Their target market is various from wastewater treatment to cement factory processes which require compressed air ranging between 0.6 and 0.8 bar gauge.

Importance Of Turbo Blower In The Manufacturing Industry

Air foil bearings enables turbo air compressors to be oil-free, to run at extremely high speeds, so it can be compact and high power density. Our air bearin.

high speed turbo blower Product

Introduction High speed bearing technology is applicable for aeration blowers operating at much higher speeds than the typical 60Hz, 3600RPM for cast multistage units. High Speed Turbo (HST) units are usually single stage (though some utilize multiple cores) and rotate from 15,000 to 50,000RPM. At such high speeds, standard roller bearings cannot offer the industry standard L10 bearing life.