Use of commercial RO filter systems for the paper and pulp industry

Bleaching protects paper against yellowing. Gas phase filtration protects equipment against corrosion. Whether using wood pulp, pulp or waste paper: bleaching is an essential process step in paper production to remove unwanted stains. Because lignin is responsible for the yellowing of paper, it needs to be removed during the bleaching process.

Paper & Pulps Delite Industries

The pulp and paper industry is unusual among the end-use applications for filtration equipment in having just one main production process, which has two parts: the production of wood pulp and the manufacture of paper from it. These two parts may be contained in one plant on one site, the fully integrated mill, or quite separately as the non.

Machines Used By Paper Pulp Manufacturers For Chemical Processing

Experience with belt filter presses in the pulp and paper industry Reid Miner National Council of the Paper Industry for Air and Stream Improvement, Inc., Gainesville, Fla. Perhaps the most dramatic changes in pulp and paper industry sludge handling practices to have occurred in this country in the last 5 years have been the significant increase in

Pulp & Paper mill AAF Air Filter แผ่นกรองอากาศ HEPA Fan Filter

The pulp and paper industry is subject to many requirements because of its high water and electricity consumption. To ensure that these requirements are met at all times, HYDAC supplies system solutions that are both sustainable and energy-efficient.. HYDAC filter element Optimicron® Pulp & Paper. For the filtration of typical paper machine.

Process Control in Pulp and Paper Production Knick

Our PowerGuard™ hydraulic and lubrication filters, remove the contaminants from within pulp and paper mill's systems and equipment with Beta 1000 efficiency, and include media add-on offerings such as water absorptive media, static dissipative media, as well as TTI's patented SmartFlow™ media technology. TTI's product offering is.

Pulp and Paper Filtration Industrial Manufacturing Pall Corporation

Aria Filtra™ has been serving the pulp and paper industry for more than 30 years. We are recognized as a leader in filtration science, improving the reliability and availability of water to reduce the total cost of operation. Unlike conventional clarifier and multimedia filters, membrane technology can easily handle upset conditions such as.

Paper technology in Pulp and Paper Industry Scan Machineries

Pulp and Paper. BOLLFILTER filtration in the paper industry. BOLLFILTER systems have proven their value in many paper application processes, such as the filtration of raw water, sealing water, process water and cooling water. Mill owners have chosen them thanks to a history of exceptional reliability and their minimal maintenance requirements.

Vacuum Drum Filters in Pulp and Paper Production

Jul. 06, 2021. Filtration is one of the indispensable key processes in the pulp and paper production process. It plays an important role in improving the cleanliness of hydraulic pressure, lubrication systems, chemicals, circulating water, and boiler feed water. The filtration system mainly includes bleach chemical preparation filtration system.

Chlorine Dioxide Pulp Bleaching & Paper Chemical Preparation Pall

A modern paper machine consumes less than 10 m 3 water per 1 ton of produced paper. This is 10 times less than some decades ago. For instance, in Finland the pulp and paper industry has succeeded in decreasing their environmental impact significantly during the past 20 years by applying biological water treatment and by closing the water circulation.

Smarter pulp & paper operation from Veolia

The global production of paper and paperboard (excluding merchant pulp) is now comfortably in excess of 400 million tonnes, with the slowing down in the USA and Europe more than offset by the growth in Asia. The Asian production is in excess of 40% of this, while close to 30% comes from Europe, and almost 25% from North America.

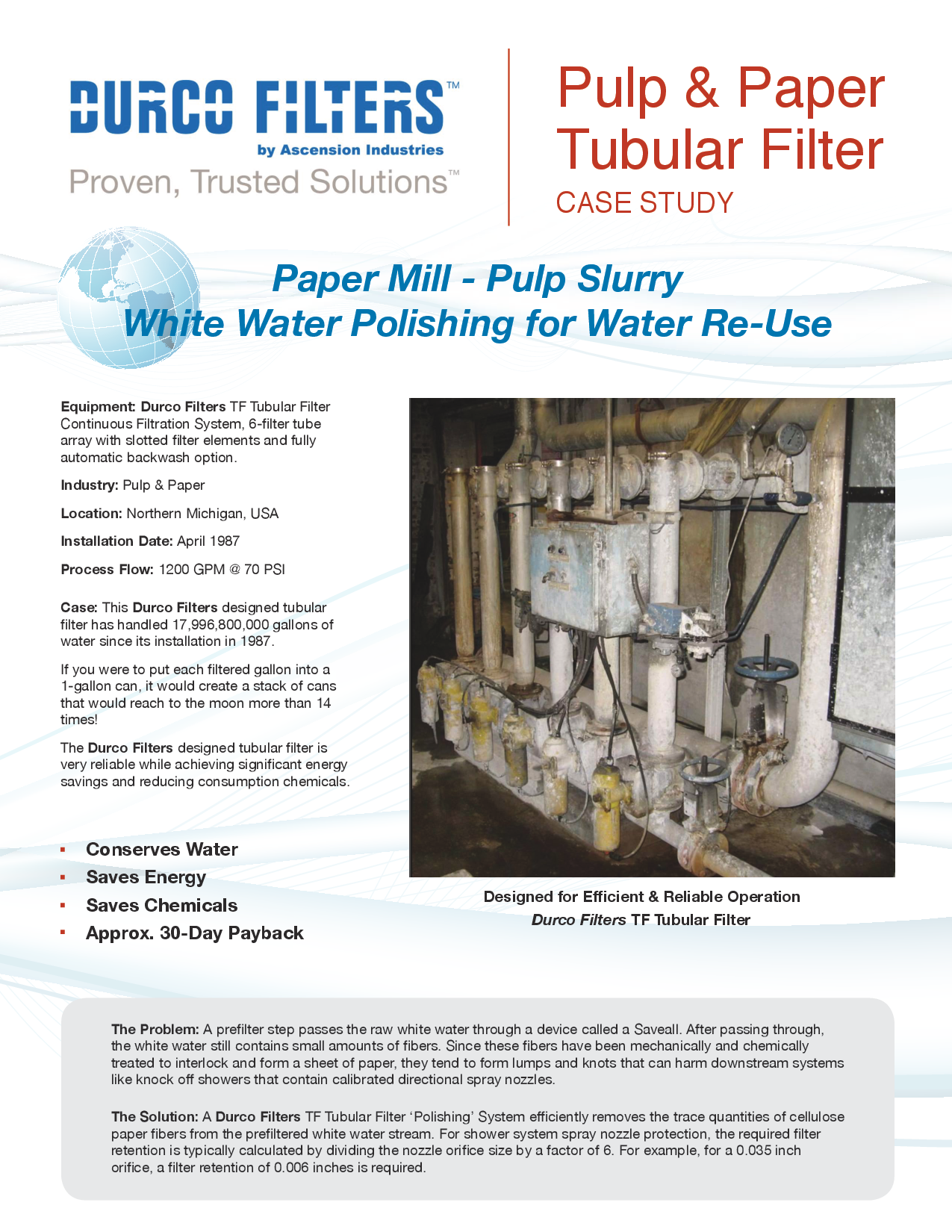

Pulp & Paper Tubular Filter

Increased recausticizing efficiency. Recausticizing processes in the chemical pulping industry require a wide range of filters. The quality of filtrated white liquor, green liquor and lime mud depends greatly on the ability of the filter fabrics to effectively filter and recover cooking chemicals for further processing.

Parason Disc Filter Pulp & Paper Machine For Industrial at best price

As a leading supplier of industrial water filtration systems for pulp and paper, Compositech's pulp and paper filtration mill customers regularly use vacuum filtration equipment for fiber recovery and for sludge dewatering. Paper mills use disc filters as savealls to recover fiber lost in the paper-making process. Additionally, disc filters are.

Pulp and Paper Screens Recycling Screens Fiber Retention

Learn about vacuum drum filters, the essential equipment used in the pulp and paper industry for separating solids from liquids. Discover the benefits, various types available, and common applications, as well as tips for maintenance and troubleshooting. Finally, explore the latest developments and future trends in vacuum drum filter technology.

[Pulp and Paper Mills] [Graymont]

The pulp and paper industry typically required a vast amount of water during various operational stages such as washing, pulping, bleaching, and paper-making. According to available data, the pulp and paper industry consumes 250-300 m 3 of water to produce 1 ton of paper (Chaudhry and Paliwal, 2018). As a result, substantial liquid waste is.

Parason Disc Filter Pulp & Paper Machine For Industrial at best price

The pulp and paper industry needs a comprehensive approach to asset protection and process optimization. Improving the reliability of process fluids to reduce total cost of operation ensures papermaking operations are more productive. Demand for pulp and paper machine process fluid filtration solutions is driven by water and energy needs.

filter for paper pulp YouTube

The global pulp and paper market size is projected to reach USD 368.10 billion by 2027. Global Filter products are widely used in the pulp and paper industry as they help attain the specific needs of various applications while providing extended service. Our target applications in the paper-making process are point-of-use condensate recovery.